Cummins Diesel History

If there's one man who had the most influence on the development of the diesel engine in America, it was Clessie Cummins.

Clessie Lyle Cummins (1888-1968)

Clessie Cummins was born on a rural farm in Indiana. Clessie was a rather bright child and quite a tinkerer, by the time he was 12 he had already built a working steam engine. In 1908 he was hired by W.G. Irwin, a successful Columbus, Indiana businessman, as a chauffer and mechanic. Irwin was impressed by young Clessie's mechanical abilities and later set up their own auto mechanics shop and put Clessie in charge.

During WW1, Clessie operated a machine shop and scored quite a few government contracts. During that time he also studied up on the compression engine design developed by Rudoph Diesel and was convinced that it could be made economically viable. In 1919 he was able to convince Irwin to put up the capital necessary to start his own engine company and Cummins Engine Company was born.

At first, Cummins produced engines under license from a Dutch company called Hvid. These were large 4 cycle single cylinder engines producing 6 HP and were only good for stationary power. They were underdeveloped and were poor sellers. Soon Clessie hired H. L. Knudsen, a former Hvid engineer, and began to work on engines of their own design.

One of Cummins' first engines.

Cummins found a market with farmers and the marine industry. Some of his engines were even sold through the Sears Catalogue, sold as "Thermoil" engines. But the Great Depression hit Cummins hard as the marine industry took a huge hit and greatly curtailed engine orders.

Facing bankruptcy for his company, Clessie came up with an idea. In 1929 he purchased a used Packard limousine and fitted one of his diesel engines in place of the original engine. The Packard was the only car with a large enough engine compartment. He took W.G. Irwin for a ride in what was Americas first diesel powered passenger car. Irwin was impressed enough to invest more money into Cummins engine company. Clessie drove the car from Indiana to the New York Auto Show, advertising it was done on $1.39 worth of diesel fuel. But when he arrived, he was prohibited from setting up a display at the autoshow. Not one to give up, Clessie rented space across the street from the Auto Show and set up his own display.

Diesels for all!

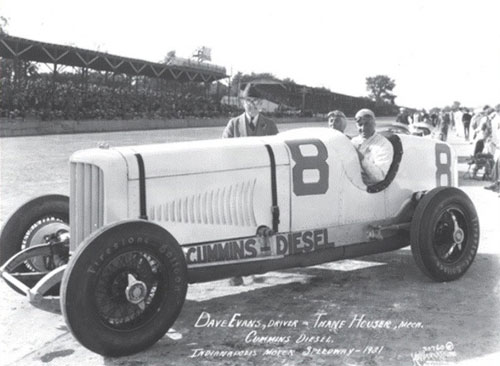

The advertising worked and Cummins began to gain customers again. Cummins installed a Model F diesel engine in a race car chassis and entered the Indianapolis 500. The diesel powered race car placed 12th and completed the race without a pit stop.

The Cummins powered Indy 500 race car.

In 1931 Cummins decided to work on getting his engine accepted in the commercial truck industry. So he fitted a diesel engine to a truck and drove cross country to prove that the diesel engine was not only reliable but economical. He boasted driving across country on $11.22 in fuel. An incident occured during that trip that would lead to a significant development in the trucking industry, but that will be discussed later.

The acceptance of Cummins engines grew and by 1937 the company finally posted a profit. During WW2, like most US companies, Cummins focused on producing engines for the war effort.

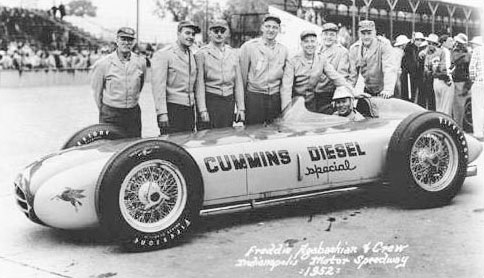

Several additional attempts were made to run diesel race cars at Indianapolis. The last was in 1952. Clessie had been experimenting with turbocharging to replace the heavy superchargers. The rules gave blown diesels a maximum displacement of a 6.6 litre. Clessie and his brother Don were hot after it with a specially built racing engine of 402.6 cubic inches, lightened with aluminum and magnesium. Output was a serious 380 horsepower.

The chassis builder was Frank Kurtis, who had been experimenting with placing the driveshaft alongside the driver's left hip, shifting weight, and lowering the overall height of the car. Mounting the engine on a horizontal plane, rather than vertical, added to the sleek design. At its cowl, the car was 23 inches tall! However, it weighed 3,100 pounds, compared to the 2,000 pound average weight of the other entries. The engine was 750 pounds on its own. Tire wear was going to be a factor if any serious racing was conducted to get the car to the lead.

Things began to look up quickly. On the first day for qualifying, as the first entrant on the track, the big diesel roadster completed its 4 lap qualification at 138.010 miles per hour, a new record. It stunned all the other 32 competitors, including Team Ferrari, the only foreign entry. The speed held, putting the car on the pole for the race. Clessie was very confident.

The main issue with the big diesel is that on initial acceleration, it could not keep up with the gasoline powered cars. Given its great speed, it quickly caught them, but it then had to pass them to regain its position. It was a worry, given that it would lead off on the pole, only to see that quickly evaporate until the initial inertia was overcome.

The Memorial Day race day flag fell, and as supposed, the roadster was passed by several cars. However, it held its own. By lap 70, the diesel began to belch huge clouds of coal black smoke, a clear indication that something was wrong. A pit stop was made, but two laps later, the car retired. Later, an inspection revealed that the air intake for the turbo charger had become clogged with bits of rubber from the race track. An ill placed inlet was the failure, not the engine itself.

The 1952 Cummins Diesel Special.

Although the car was forced out of the race without finishing, the engine design concept proved sound, with the “pancake” diesel engine design used in thousands of installations world wide in bus applications.

Cummins and trucking

The trucking industry started really growing during the 1950's. In the mid 1950's, Cummins introduced the Cummins NH220 engine, a naturally aspirated 6 cylinder diesel displacing 743 cubic inches and produced 220 hp, which at that time was considered a lot. In 1957 the N series engine was boosted to 855 cubic inches with turbochargers and aftercoolers being added in later years. The 855/N series block, while having many updates is still produced today in it's basic form as the Cummins N14.

Cummins NH220 engine and an N14 engine

Cummins saw the advantage of international production. In 1956, the first overseas factory, in Shotts Scotland, was opened. By the end of the 1960's, Cummins had a network of over 2,500 dealers in 98 countries. The 1960's also saw the development of more modern smaller industrial engines, in a way going back to the roots of the company. Clessie passed away in 1968 but not before seeing his company become an international success.

Life after Clessie

The 1970's and 80's were met with both a need for cleaner engines (the clean air act) and fuel efficiency (the fuel crisis) without sacrificing performance. Cummins offered the NTC series engines, which provided good performance with both low emissions and fuel consumtion. But for plain old fashioned brute force, Cummins offered the KTA, an engine offering 450, 500, 525 and 600hp outputs displacing 19 litres. Even today 500-600 hp is considered high, but in the 1970's and early 80's, the average engine produced 300-350 hp and 400-425 hp were considered premium power output. The KTA series engines still hold the record for the largest displacement engine ever sold for on-road use.

Cummins KTA-525

Cummins would enter the 90's and beyond with sophisticated electronic controls that allowed engines to have not only higher performance and high fuel economy numbers, but be cleaner burning.

The compression brake

Remember that incident mentioned ealier? During his 1931 cross country trip to promote diesel engines in trucks, Clessie and his crew almost died during a descent down Cajon Pass on old US66 in California. Their brakes overheated and failed and the truck ended up nearly crashing.

"About dusk on the fifth day, we reached the top of Cajon Pass west of Barstow, California. Before retiring to the sleeping compartment, Dave had warned me against this thirty-five-mile stretch of mountainous down-grade. "Wake up Ford and me when you get to Kayhone Pass," I had understood him to say, "I don’t want to be in this box when you start down that twister with the kind of brakes we’ve got." I had heard but not seen, my Spanish being nonexistent, the word Cajon failed to register when the sign appeared. Soon, however, I realized my error. The brakes wouldn’t hold. Now running in third gear, I tried desperately to get into a lower speed. Nothing doing. I saw I would just have to ride it out. Well down the long grade by now,I suddenly saw something moving across the road ahead. There was along dark shadow and then a red glow flared in the sky. I realized with new alarm that a freight train was cutting across our path. The truck roared on. Dave and Ford screamed bloody murder in the compartment behind me. And I clung to that steering wheel like a madman. Had Mack Sennett been on hand with a movie camera, he would have gotten enough footage for one of his famous Keystone Kops features. As we raced inexorably toward the crossing and doom, the train's caboose loomed out of the darkness. Its red lights cleared the highway just as we reached the tracks. We had escaped certain death by inches." - Clessie Cummins

Clessie knew that the engine already provided some compression braking on it's own, but felt that there must be a way to amplify that compression ability. He vowed to somehow make his engines work downhill just as well as they did uphill. He shelved the idea for the next 20 years and in 1955 started working on the idea. He was already retired from Cummins but that didn't stop him from coming up with new ideas. With his son Lyle and a machinist friend named Ray Hansen, he formed CENTCO (Cummins Enterprises Company), which was little more than Clessie's think tank in the basement of his home. They finally figured out that it was indeed possible to amplify the braking ability of the engine but were unable to come up with a way to do it that would follow the engine's timing.

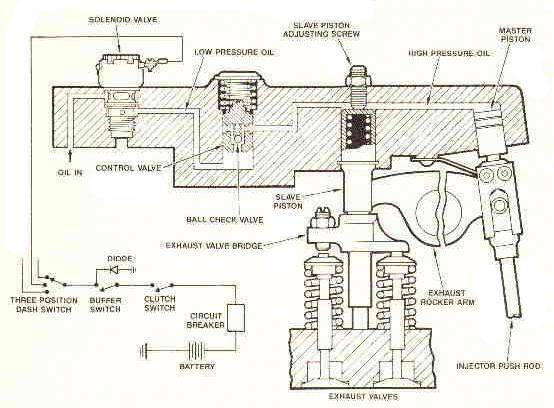

In 1957 during a sleepless night in a Phoenix, AZ motel room, Clessie came up with the right idea. The camshaft on the Cummins N series, had 3 cams, one to open the intake valves, one to open the exhaust valves and one to activate the fuel injector plunger. A mechanism on the engine would cause the fuel injector cam to actually activate the exhaust valve at injection time, so instead of injecting fuel, the compressed air would be released. Without the combustion of fuel in the cylinder to create power, the engine was turned into a power robbing air compressor. Clessie filed his patent in shortly thereafter.

The first vehicle equipped with a CENTCO designed compression brake was a 1955 GMC Suburban Carryall repowered with a Cummins JN-6 engine. The vehicle had to be extensively modified to handle the large 401 cubic inch engine. Downhill tests were encouraging. The Suburban, weighing in at 6,500 lbs, was able to slow from governed speed (2,500 rpm) to idle speed in 200 yards on a 30% grade using nothing but the engine brake.

The Cummins NH series engines were very popular among the trucking industry and CENTCO developed one to fit, they used the N series marine engines on Clessies yacht as test mules. They simulated downhill braking situations using 4 of the cylinders to power the other two.

But they needed more testing, so in 1959 they equipped an Cummins NH powered truck owned by Sheldon Oil Company of Suisun, California. The truck was piloted by Bill Hill, an 18 year veteran truck driver. The test run was on US50 outside of Lake Tahoe. Mr. Hill was so impressed with the performance he stated he never wanted to drive another truck unless it was equipped with Clessie's engine brake.

Due to a contractual agreement, CENTCO was required to first present their ideas to their parent company Cummins. Cummins failed to see any promise in the idea and passed on it. All the other major diesel engine makers of the time passed as well.

Now here's where things take an interesting turn. Clessie's nephew Don was set up on a blind date with Roberta Englund, the daughter of Bob Englund, the Vice President of Jacobs Manufacturing Company. Don and Roberta hit it off and eventually married. Bob was introduced to Clessie and Lyle through Don's father Delosse Cummins. The brass at Jacobs Manufacturing, which specialized in drill chucks, was looking to diversify. Through Bob Englund, they caught wind of the compression brake idea, they thought it might be a wise investment. By 1961, the first compression brakes for the Cummins NH series engine were available commercially through Jacobs and the "Jake brake" was born.

Jake Brake schematic

Clessie was able to fulfill his promise to make his engines go downhill just as well as they did uphill.

Possibly the most advanced engines from Cummins to date: The Signature 600 and ISX.

The Jacobs "Jake Brake" is an add-on feature. However Cummins later took it one step forward. In the late 1990's they released their all new Signature 600 engine. The Signature 600 produced 600 hp and 2050 lb/ft of torque. It was Cummins first 600 hp engine since the KTA-600. They designed it with a DOHC cylinder head. The second cam was designed specifically for the engine brake. Called the Intebrake, the compression brake in the Signature 600 engine was built into the engine. It was effective enough that allowed the engine to provide a full 600 braking horsepower, enough to keep a 40ton semi well under control on downgrades. The engine was also 300 lbs lighter than similarly sized engines, despite having a larger displacement of 15L. Despite it's high output the Signature 600 was suprisingly efficient. Unfortunately, the large amount of torque put out by the Signature 600 limited the choices in transmissions and other driveline components.

The Signature 600 and ISX

The long-running N14, which was the final version of the venerable 855 cu in block, as well as the Signature 600 was replaced by the ISX series. The ISX incorporated the technical advances of the Signature 600 but was also available in lower HP versions, from 400 hp to 565 hp (600hp is available with software upgrades, though with a lower 1850 lb/ft torque rating, allowing for better flexibility in driveline choices.). The ISX was compliant to the 2002 EPA requirements. The ISX used cooled EGR in order to comply with the new levels of NOX. It was also the first engine to be certified to the EPA's 2.5 gram standard.

The ISX was also available with Cummins CELECT electronics and CENTINEL oil management system, which allows up to 50,000 miles between service intervals.

Original material ©1996-2026 Mr. Sharkey | All rights reserved